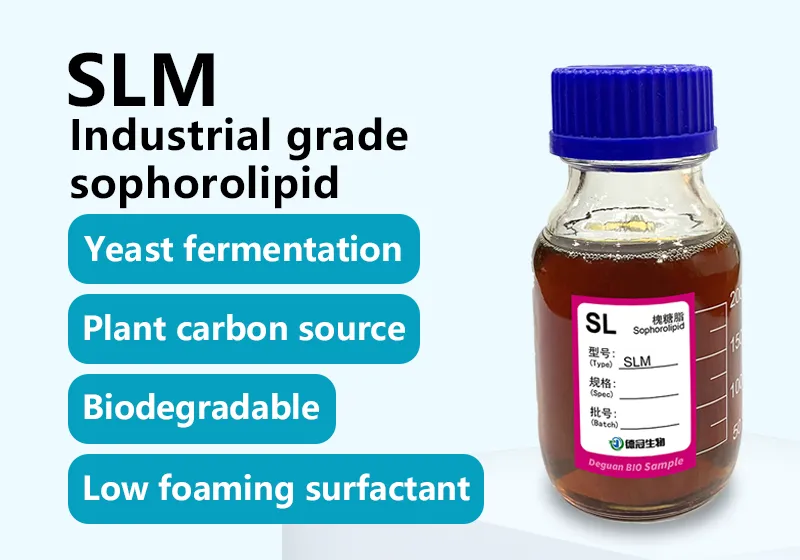

Basic Information

Product model: SLM

Product appearance: Brown flowable liquid

Effective substance content: ≥350g/L

Usage: Industrial fields and other general industries

Packaging specifications: 25kg、200kg、1000kg

Product Description

Sophorolipid is a glycolipid biosurfactant synthesized and metabolized by Candida albicans using food-grade sugar and vegetable oil as carbon sources through a fermentation process under certain conditions. SLM is the crude extract of sophorolipid fermentation broth, which contains both lactone-type sophorolipid and acid-type sophorolipid. The product is soluble in water and some organic solvents, resistant to high temperatures and high salts, and is a low-foaming surfactant. It has excellent surface properties, is non-toxic, easily biodegradable, and environmentally friendly.

Physical and chemical indicators

Features

Sophorolipid SLM is an industrial-grade hybrid product. It is a biosurfactant with excellent surface properties and has the functions of reducing surface tension, emulsifying, wetting, decontaminating, and foaming. It can be used in oil exploration, pollution control, soil remediation, agriculture, feed and other fields. Its characteristics are as follows:

1) Excellent surface properties: Sophorolipid solution with a concentration of 1‰ can reduce the surface tension to 26-35mN/m. The CMC concentration of sophorolipid is <20mg/L.

2) Low-foaming products: Sophorolipid products are low-foaming surfactants and can be used in applications that require low foaming.

3) Good tolerance: It has been experimentally measured that sophorolipids can withstand high temperatures of 150°C and salt concentrations of 100,000mg/L, while still maintaining stable structure and performance.

4) Safety and environmental protection: Sophorolipids are rapidly biodegradable and the finished product does not contain heavy metals.

Precautions:

1) It is not recommended to use it under the conditions of 10<pH<3.

2) Although the product can withstand high temperatures, it is still recommended that the optimal use temperature is between 10-80°C.

3) In industrial-grade products, fermentation by-product impurities sometimes precipitate, but the physical properties of the precipitates are relatively stable and will not affect performance.