Basic Information

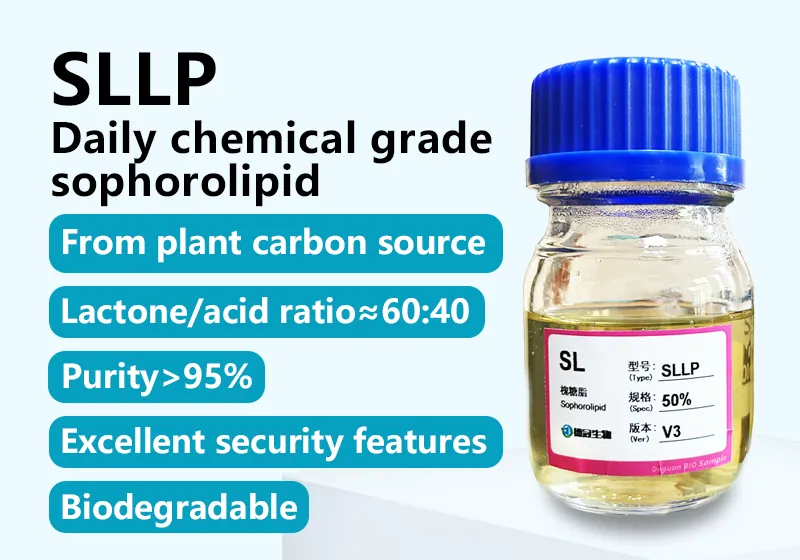

Product model: SLLP

Product appearance: Light yellow to brown liquid

Effective substance content: 50%

Usage: Daily chemical field

Packaging specifications: 25kg

Product Description

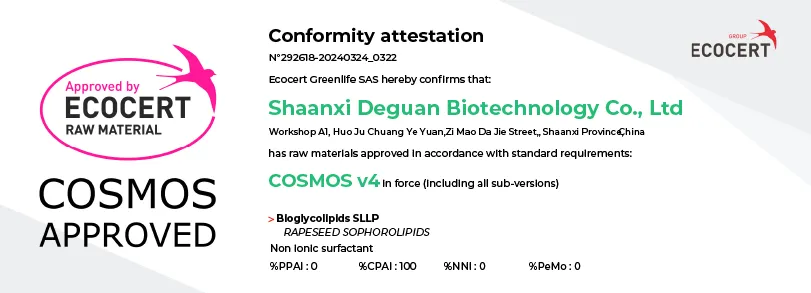

Bioglycolipid SLLP is a sophorolipid surfactant produced by fermentation process. Its molecular structure includes lactone sophorolipid and acid sophorolipid. It is made from food-grade sugar and vegetable oil as carbon sources, which are then purified and concentrated. The product is easily soluble in water and some organic solvents, resistant to high temperatures and high salts, and has moderate foam volume. It has excellent surface properties, is non-toxic, easily biodegradable, and environmentally friendly. It can be used in various civilian fields such as daily chemicals, cleaning, and home care.

100% Agro-Ingredients

Physical and chemical indicators

Lactone:Acid≈50:50

Features

Bioglycolipid SLLP is a biosurfactant with excellent surface properties and excellent performance. Its characteristics are as follows:

1) Excellent surface properties: SLLP solution with a concentration of 1‰ can reduce the surface tension to 26-35mN/m. Its CMC concentration is only <20mg/L.

2) Multifunctional: Through formula control, it can achieve cleaning, foaming, emulsifying, moistening, solubilizing, moisturizing, skin care and other functions.

3) Strong bactericidal properties: SLLP has strong bactericidal properties and can dissolve and kill bacteria, fungi and viruses. Can be used in acne care and anti-dandruff products.

4) Good tolerance: Experimentally measured, SLLP can withstand high temperatures of 150°C and salt concentrations of 100,000mg/L. Stable performance over a wide pH range. The hard water resistance performance tested by the national standard method reaches level 5.

5) Safety and environmental protection: Skin irritation test is level 0, and it has rapid biodegradability according to OECD standard test.

Precautions:

1) It is not recommended to use it under the condition of 5℃>temperature>150℃.

2) Avoid using it with strong acids, strong bases, and strong oxidants.

3) Generally, no preservatives are added to the product when it leaves the factory.